Advantages and Disadvantages of Socket Weld fittings

Release Time:

Mar 18,2024

Socket weld fittings are commonly used in piping systems for their ease of installation and ability to withstand high pressure and temperature. One of the main advantages of socket weld fittings is their ability to provide a strong and leak-proof connection.

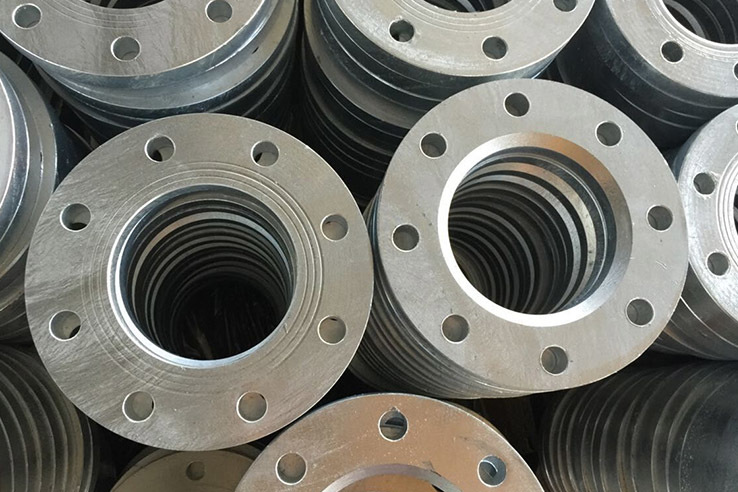

Socket weld fittings are commonly used in piping systems for their ease of installation and ability to withstand high pressure and temperature. One of the main advantages of socket weld fittings is their ability to provide a strong and leak-proof connection. This is achieved by welding the fitting to the pipe, creating a seamless joint that is resistant to leakage. Additionally, socket weld fittings have a clean and smooth appearance, making them aesthetically pleasing in piping systems.

However, socket weld fittings also have some disadvantages. One of the main drawbacks is that they require more time and skill to install compared to other types of fittings. The welding process can be complicated and may require the use of specialized equipment and trained personnel. Additionally, socket weld fittings are not as easily disassembled as threaded fittings, making maintenance and repairs more challenging. Furthermore, socket weld fittings are not suitable for use in applications where the pipe needs to be frequently disconnected and reconnected.

In conclusion, while socket weld fittings offer several advantages such as a strong and leak-proof connection, they also have some drawbacks such as the complexity of installation and limited disassembly capabilities. It is important to carefully consider these factors when choosing the appropriate fitting for a piping system.

Keywords:

More information