Ouhao Pipeline Equipment

Keyword:

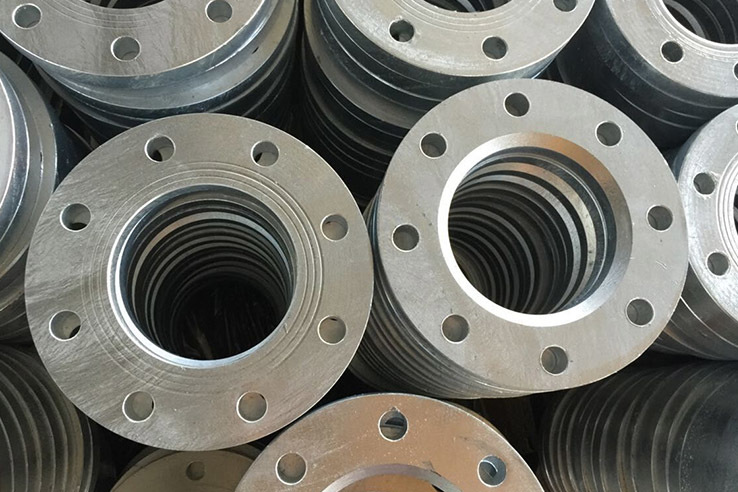

What are the materials of flanges

Carbon steel flange. This is the most common flange material, mainly composed of carbon and iron, the price is relatively low, suitable for a variety of environments and occasions, such as municipal engineering, shipbuilding, chemical, oil, natural gas and so on. Carbon steel flanges have high strength and poor corrosion resistance, and need to be regularly maintained and replaced.

Keywords:

Why does the tee need to do the blasting before painting?

Blasting before painting is an essential step in the process of preparing a tee for coating. The main reason for blasting is to remove any impurities, contaminants, rust, or old paint from the surface of the tee. These impurities can prevent the paint from properly adhering to the tee, leading to premature paint failure and corrosion.

Keywords:

Advantages and Disadvantages of Socket Weld fittings

Socket weld fittings are commonly used in piping systems for their ease of installation and ability to withstand high pressure and temperature. One of the main advantages of socket weld fittings is their ability to provide a strong and leak-proof connection.

Keywords:

General application of pipe flanges

A pipe flange is a method of connecting pipes, valves, pumps and other equipment to form a piping system. It also provides easy access for cleaning, inspection or modification. Flanges are usually welded or screwed.

Keywords:

Advantages and Disadvantages of Socket Weld fittings

Radiography is not practical on the fillet weld; therefore correct fitting and welding is crucial. The fillet weld may be inspected by surface examination, magnetic particle (MP)

Keywords:

Why does the tee need to do the blasting before painting?

Before painting, pipe tees must do the blasting. The blasting process adopt compressed air to form a high speed jet beam, spraying the material on the surface of the tees

Keywords:

Latest News