Categories

Contact Us

Office:

300 meters north of Xingwu Street, Mengcun County, Cangzhou City, Hebei Province, China

Hotline:

0086 0317 6859219

E-mail:

info@hbohgd.com

Phone:

0086 13283226888

Alisa E-mail:

info7@hbohgd.com

Alisa Wechat/WhatsApp:

0086 18831707666

ANSI B16.5 Slip-on Flanges

specializes in the manufacture of flanges, butt weld pipe fittings in standard as well as special parts and forgings according to customer drawings.

- Commodity name: ANSI B16.5 Slip-on Flanges

- Description

- 参数

-

Product Description

Slip-on flanges has a low hub because the pipe slips into the flange prior to welding. It is welded both inside and out to provide sufficient strength and prevent leakage. Slip-on flanges are all bored slightly larger than the O.D. of the matching pipe They are preferred over welding neck flanges by many users due to their lower inital cost, but final installation cost is probably not much less than that of the welding neck flange because of the additional welding involved.

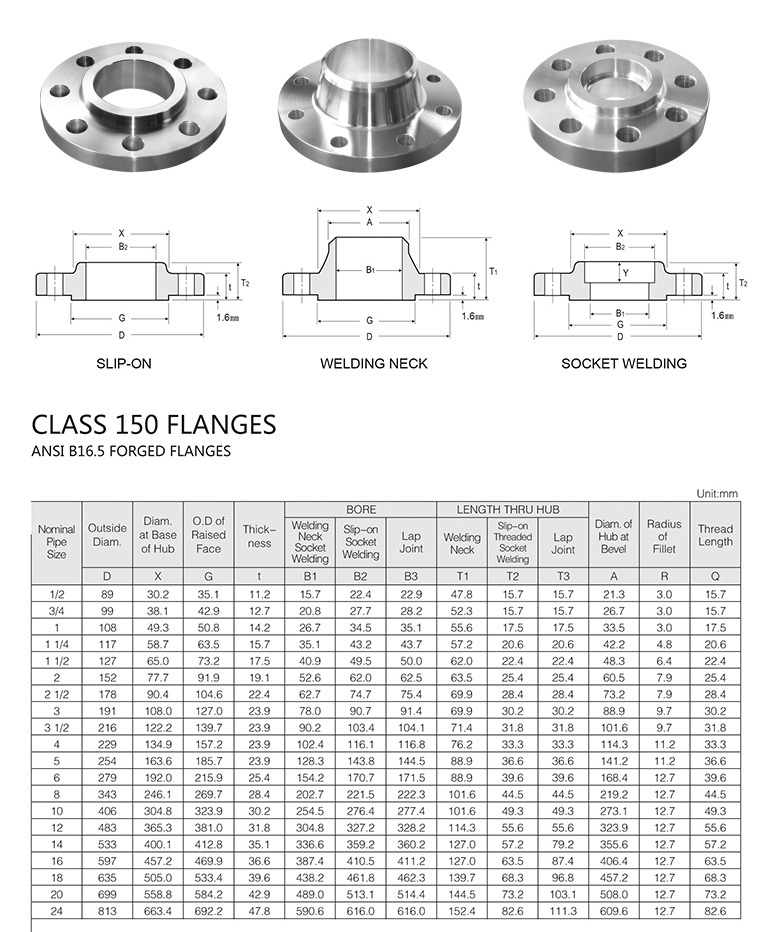

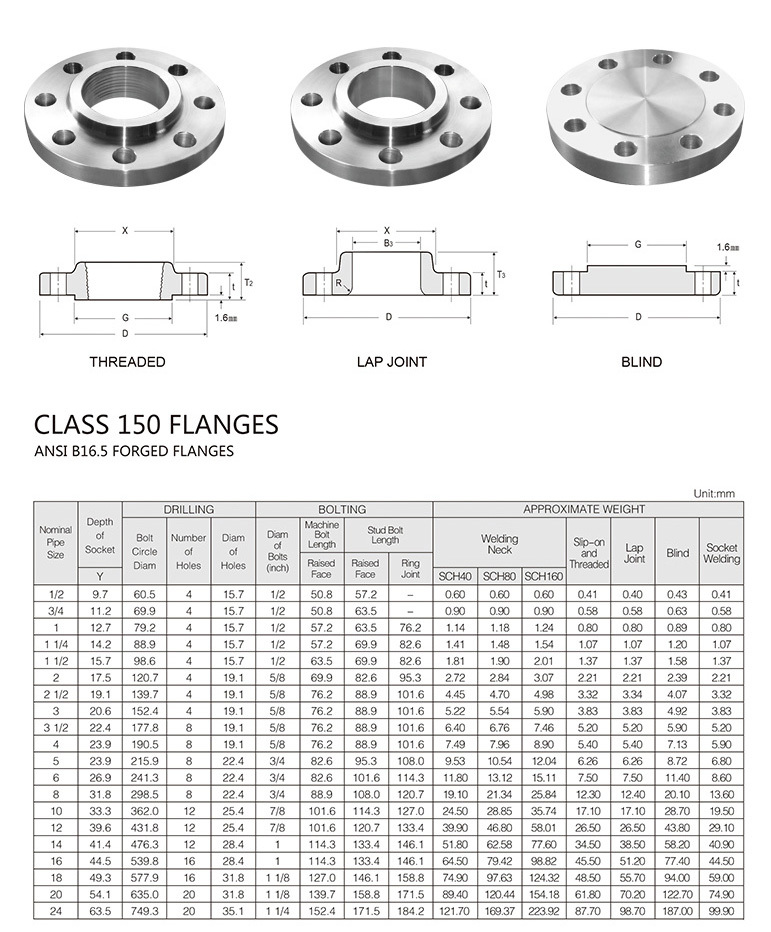

CLASS 150LBS FLANGE

Notes

(1) For the 'Bore'(B1) other than Standard Wall Thickness, Refer this

(2) Class 150 flanges except Lap Joint will be furnished with 0.06" (1.6mm) raised face, which is included in 'Thickness' (t) and 'Length through Hub' (T1), (T2).

(3) For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees.

(4) Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

(5) The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness(t).

(6) Depth of Socket (Y) is covered by ANSI B16.5 only in sizes through 3 inch, over 3 inch is at the manufacture's option.

CLASS 300LBS FLANGE

Notes

(1) For the 'Bore'(B1) other than Standard Wall Thickness, Refer this

(2) Class 300 flanges except Lap Joint will be furnished with 0.06" (1.6mm) raised face, which is included in 'Thickness' (t) and 'Length through Hub' (T1), (T2).

(3) For Slip-on, Threaded, Socket Welding and Lap Joint Flanges, the hubs can be shaped either vertical from base to to or tapered within the limits of 7 degrees.

(4) Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

(5) The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness(t).

(6) Depth of Socket (Y) is covered by ANSI B16.5 only in sizes through 3 inch, over 3 inch is at the manufacture's option.

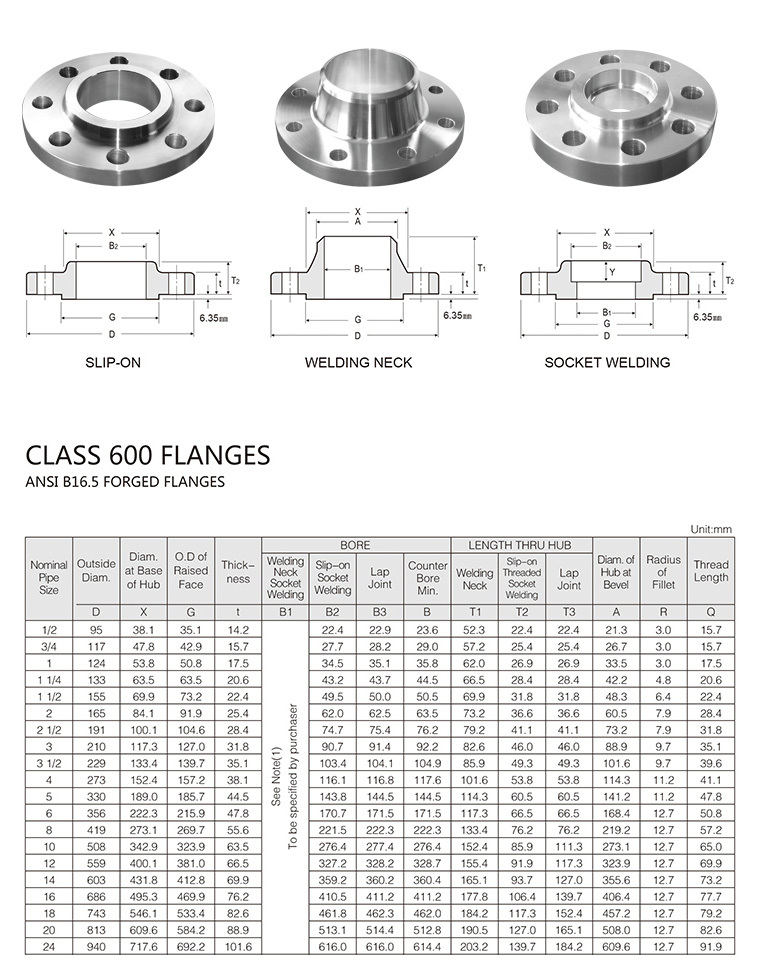

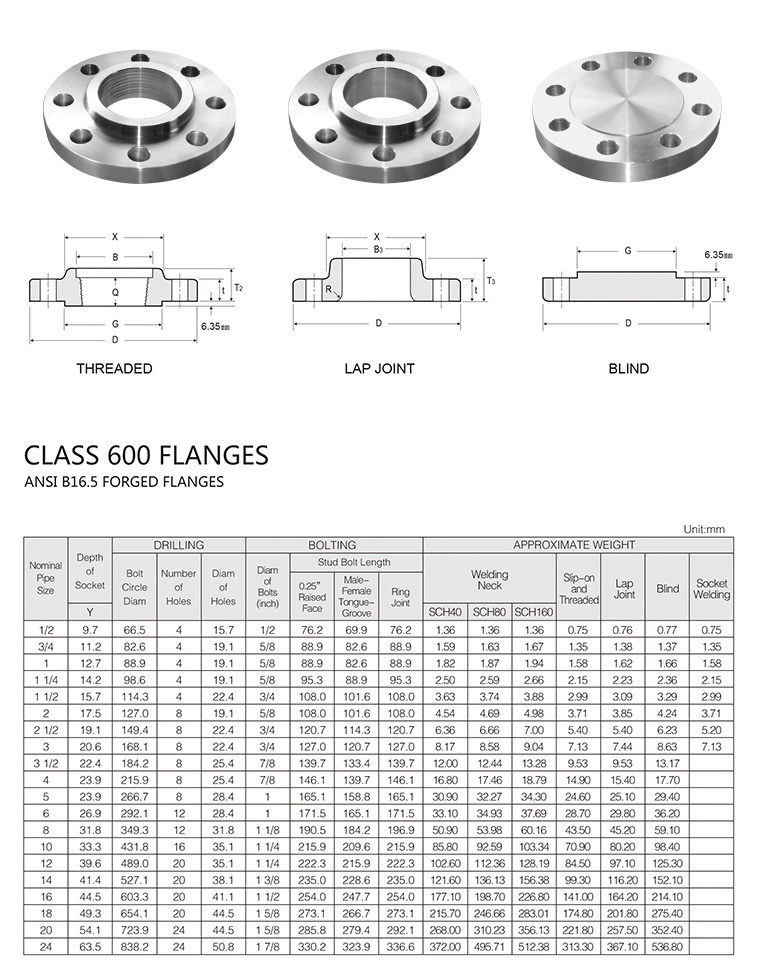

CLASS 600LBS FLANGE

Notes

(1) For the inside diameter of pipes (corresponding to‘Bore’(B1) of Welding Neck Flanges), Refer this

(2) Class 600 flanges except Lap Joint will be furnished with 0.25" (6.35mm) raised face, which is included in 'Thickness' (t) and 'Length through Hub' (T1), (T2).

(3) For Slip-on, Threaded and Lap joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees.

(4) Blind Flanges may with the same hub as that used for Slip-on Flanges or without hub.

(5) The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (t).

(6) Dimensions of sizes 1/2" through 31/2" are the same as for Class 400 Flanges.

(7) Depth of Socket (Y) is covered by ANSI B16.5 only in sizes through 3 inch, over 3 inch is at the manufacture's option.

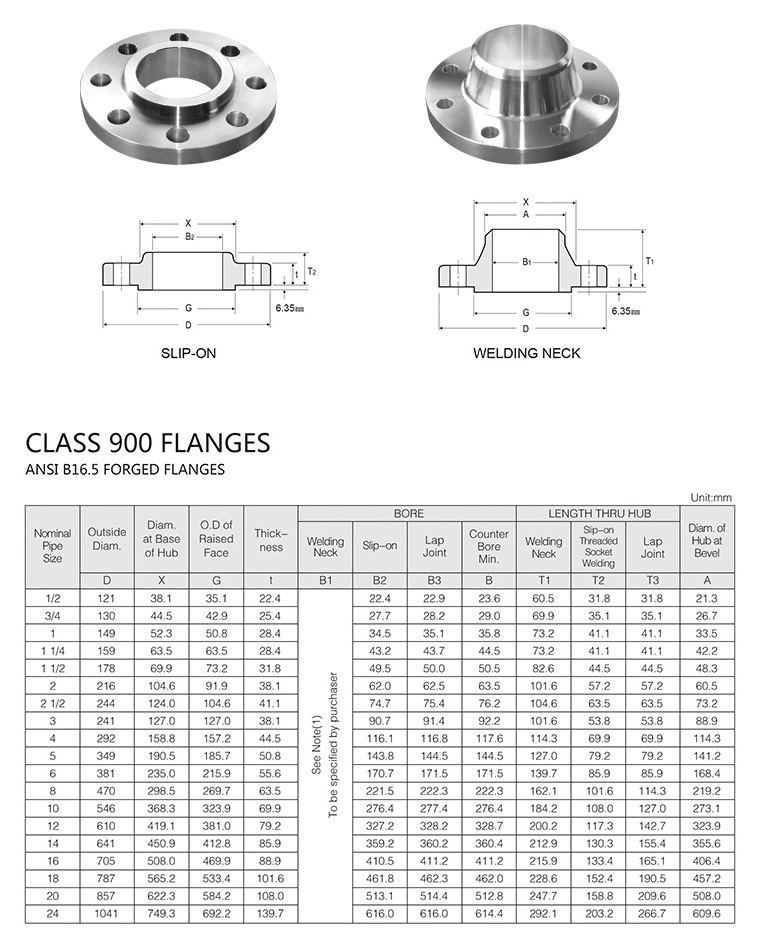

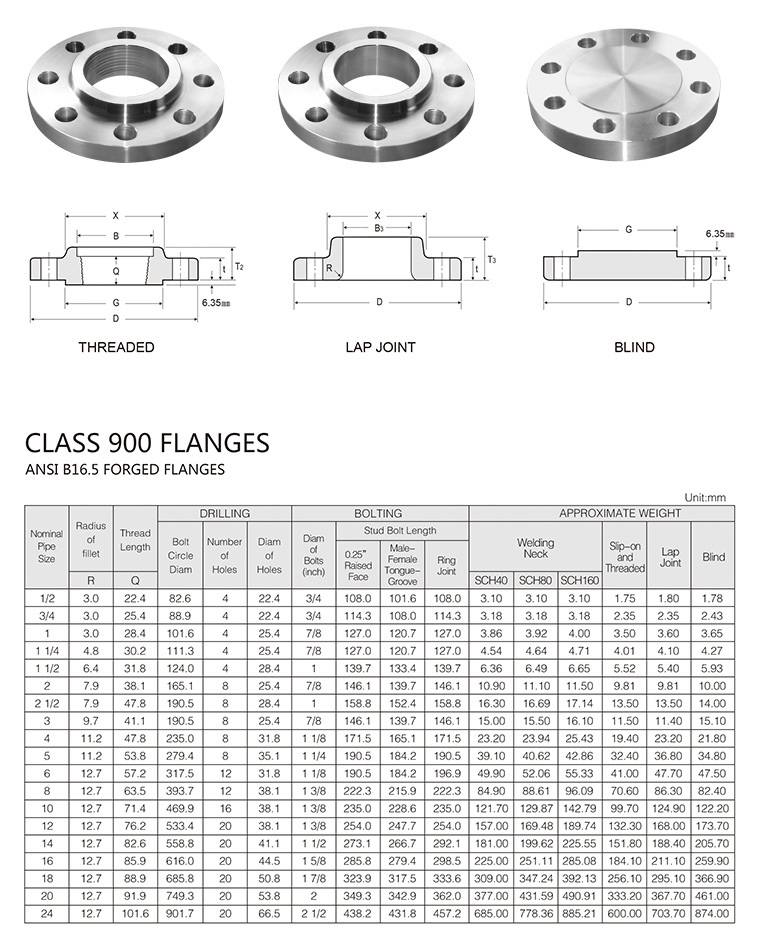

CLASS 900LBS FLANGE

Notes

(1) For the inside diameter of pipes (corresponding to‘Bore’(B1) of Welding Neck Flanges), Refer this

(2) Class 900 flanges except Lap Joint will be furnished with 0.25" (6.35mm) raised face, which is included in 'Thickness' (t) and 'Length through Hub' (T1), (T2).

(3) For Slip-on, Threaded, and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees.

(4) Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

(5) The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (t).

(6) Dimensions of sizes 1/2" through 21/2" are the same as for Class 1500 Flanges.

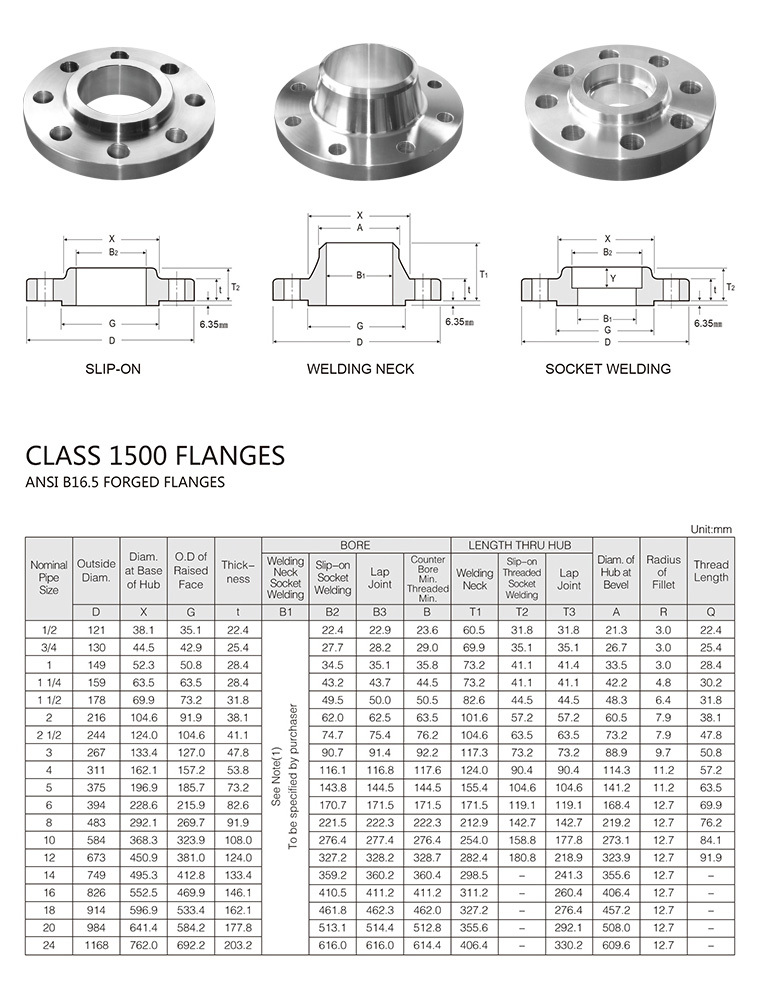

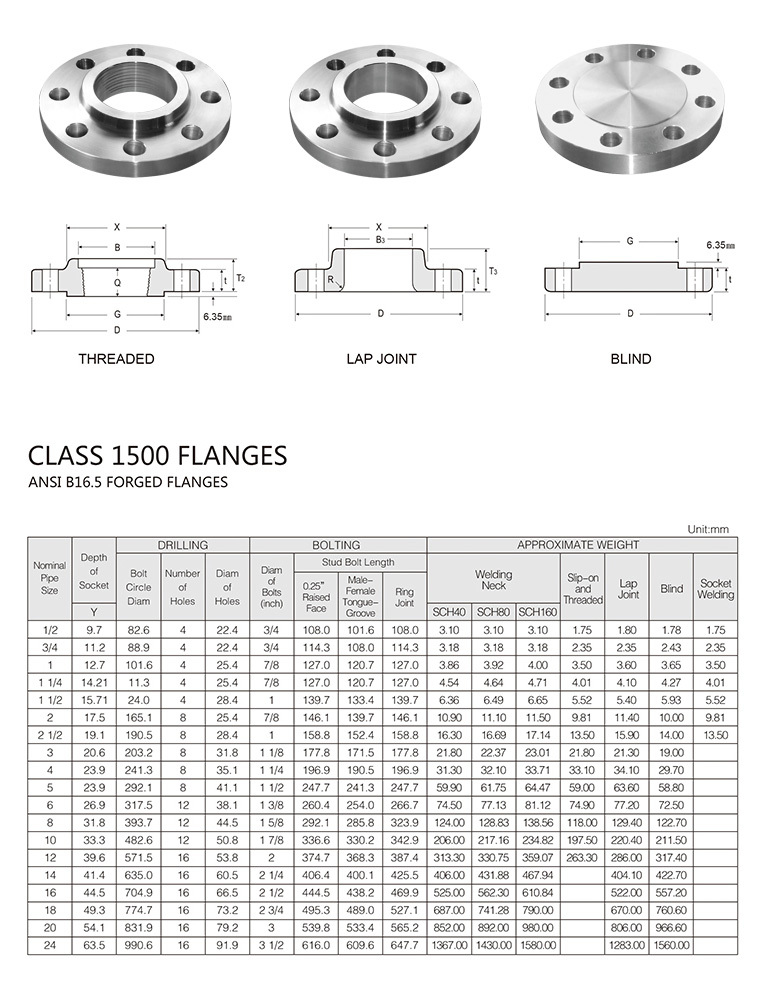

CLASS 1500LBS FLANGE

Notes

(1) For the inside diameter of pipes (corresponding to ‘Bore’(B1) of Welding Neck Flanges), Refer this

(2) Class 1500 flanges except Lap Joint will be furnished with 0.25" (6.35mm) raised face, which is not included in 'Thickness' (t) and 'Length through Hub' (T1), (T2).

(3) For Slip-on, Threaded Lap Joint and Socket Welding Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits 7 degrees.

(4) Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

(5) The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, and facing is carried out according to MSS SP-9, without reducing thickness (t).

(6) Dimensions of sizes 1/2" through 21/2" are the same as for Class 900 Flanges.

(7) Depth of Socket (Y) is covered by ANSI B16.5 only in sizes through 21/2 inch, over 21/2 inch is at the manufacturer's option.

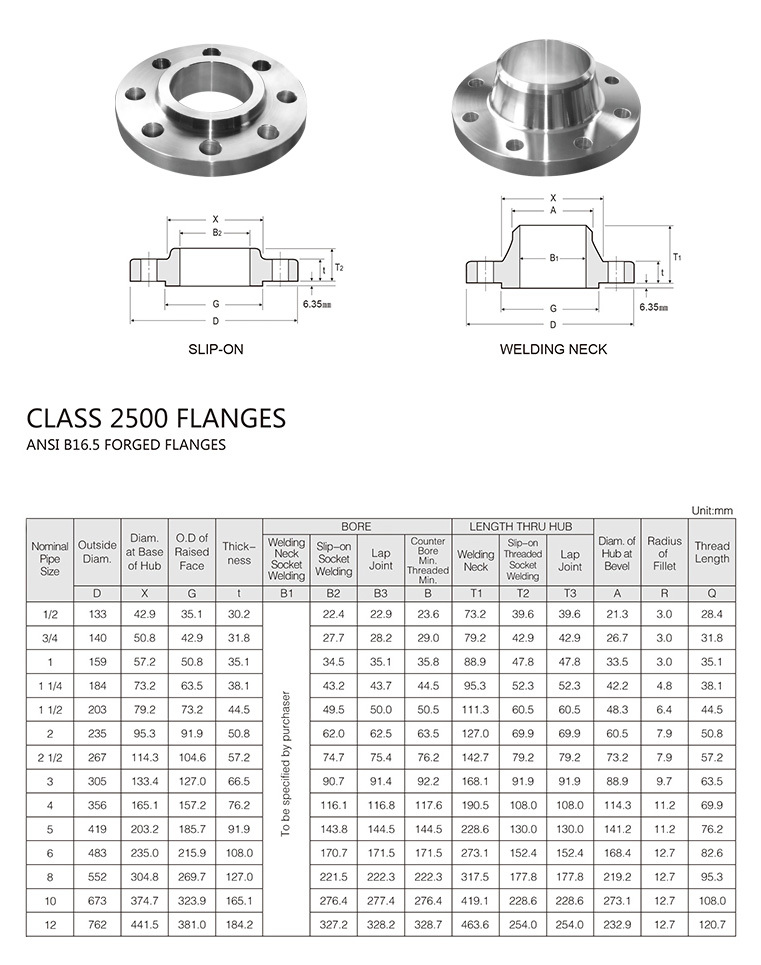

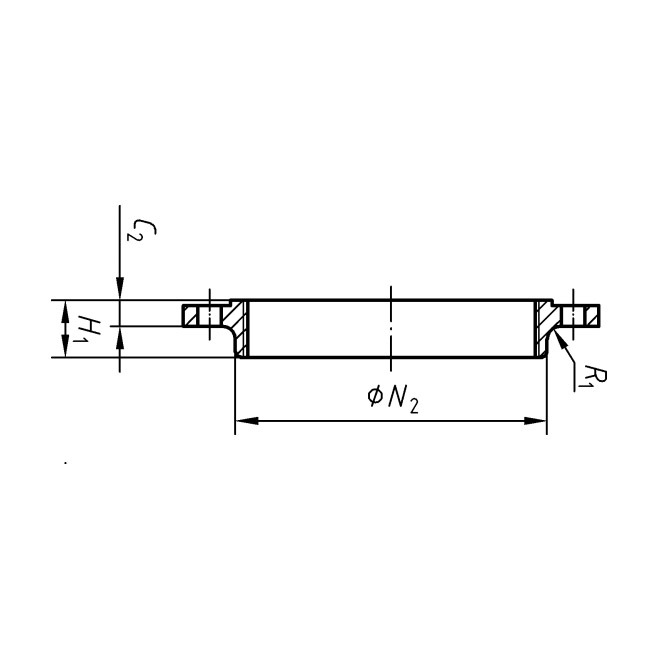

CLASS 2500LBS FLANGE

Notes

(1) For the inside diameter of pipes (corresponding to ‘Bore’(B1) of Welding Neck Flanges.), Refer this

(2) Class 2500 flanges except Lap Joint will be furnished with 0.25" (6.35mm) raised face, which is included in Thickness (t) and 'Length through Hub' (T1), (T2).

(3) For Slip-on, Threaded and Lap Joint Flanges, the hubs can be shaped either vertical from base to top or tapered within the limits of 7 degrees.

(4) Blind Flanges may be made with the same hub as that used for Slip-on Flanges or without hub.

(5) The gasket surface and backside (bearing surface for bolting) are made parallel within 1 degree. To accomplish parallelism, spot facing is carried out according to MSS SP-9, without reducing thickness (t).

(6) Class 2500 Slip-on Flanges are not covered by ANSI B16.5, slip-on flanges are at the manufacturer's option.

Package

-

-

Payment & Shipping Terms:

- Minimum Order Quantity: 2TONS

- Packaging Details: PLYWOOD CASES AND PALLETS

- Payment Terms: L/C, D/P, T/T

- Delivery Time: 10-45DAYS

- Supply Ability: 5000TONS/MONTH

-

Product Details:

- Place of Origin: CHINA

- Brand Name: XINFENG

- Certification: ISO, CE

- Model Number: ANSI B16.5 CLASS 150LBS-2500LBS

- Pressure: CLASS 600LBS FLANGE

- Material: Carbon steel ASTM A105/A105N; A694 F42-F70; A-350 LF1/LF2; Stainless steel ASTM A182 F304/304L; F316/316L; F321; F51; Alloy steel ASTM A182 F11/F12/F22

-

Key words:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!